Digital Solutions

Services that matter

Data-based insights: With the growing complexity of plant operations, the need for digital solutions has become paramount. As your Jenbacher system’s original equipment manufacturer (OEM), INNIO Group offers the myplant intelligent digital platform, which helps you manage your plant operations – and increase your profitability – throughout their life cycle. Our cloud-based myplant technology embeds analytics and digital solutions in our offerings. Today, we manage more than 12,000 Jenbacher engines remotely – delivering more than 1,200 billion data points annually.

Interested? We’ll connect with you. For optimal performance, Jenbacher Services has your power plant covered.

Why the OEM?

Exceptional insights

Your OEM digital solution advantages

Engine management and business planning through increased transparency

Remote issue resolution with more than 60% technical issues solved

Predictive maintenance via continuous monitoring and early issue detection and resolution

Profitability with our all-in-one energy management solution1/2

Our portfolio

A full suite of digital support

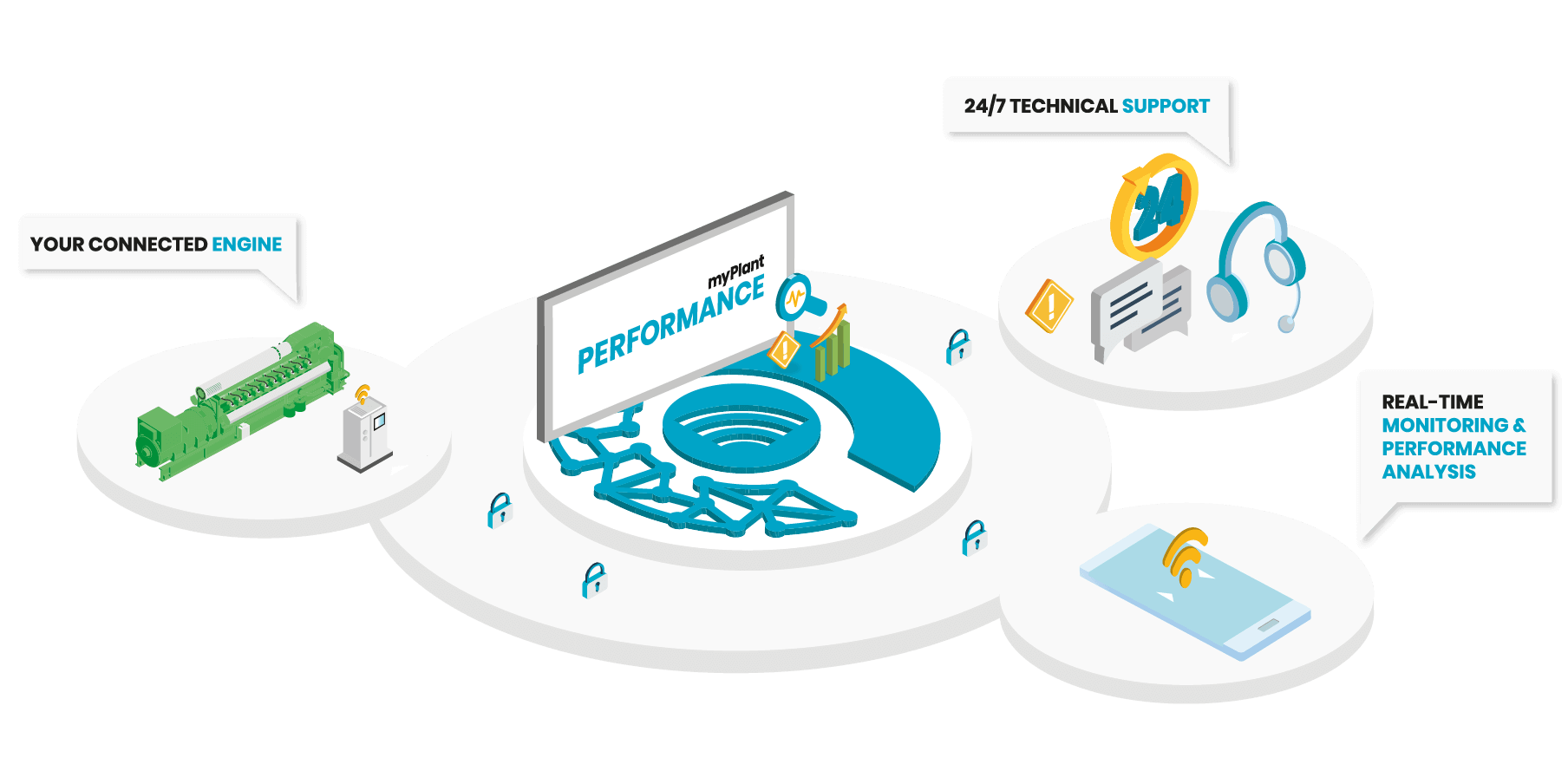

In the last decade, we learned from you and developed a comprehensive portfolio of digital solutions that support your needs. Today, we are constantly expanding this suite of digital support, and our work with you continues. Our global cloud-based myplant platform actively supports you in your systems’ operations and site improvement. Available anywhere and at any time through any digital device, myplant helps you manage your operations from the office or on the go.

Two main product lines

myplant Performance

Take your system to the next level with myplant Performance. INNIO’s digital cloud-based technology focuses on increasing your plant’s uptime and efficiency and reducing your life-cycle costs while maintaining high security standards. Experience the benefits of more intelligent, data-driven asset management, and take your operations to a new level.

myplant Optimization

See increased profitability with myplant Optimization. By intelligently combining market prices and heat forecasts with your operations’ economic, governmental, and operational costs, INNIO’s all-in-one energy management solution allows you to easily manage your heat- and energy-creating operations through constant adjustments to operational challenges. Together with you, our customers, we developed this modular system tailored to your specific needs – whether you are a biogas farmer or a heat and energy provider – to meet the challenges of the new dynamic world.

The economic value you gain

Investing in Jenbacher digital solutions pays off

24/7

Remote monitoring

diagnostics and

analytics

Reduce unplanned downtime

> 60%

Remote fix rate

Fewer service technicians dispatches

145,000

Avoided costs2

Case Studies

myplant brings more efficiency to greenhouses in the Netherlands

Jacco Besuijen, Energy manager at Prominent Greenhouse, the Netherlands

Bad Reichenhall (GER)

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

myplant brings more efficiency to greenhouses in the Netherlands

Jacco Besuijen, Energy manager at Prominent Greenhouse, the Netherlands

Bad Reichenhall (GER)

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

Consult an expert

Send us a message and we’ll contact you to start the conversation.

Whether you are looking to address your basic service needs – from maintenance requests to day-to-day spare part and consumable requirements – to technical training for your workforce, digital solutions, or even system development plans, our Jenbacher Services experts can advise you on the solution that will be right for you.

1 Available in selected countries.

2 e.g., with a J620 (3.3 MW): With a J620 (3.3 MW) engine, a shutdown of six to eight weeks could trigger a shortfall of €145,000, depending on feed-in tariffs and downtime