Coal Mine Gas

The green side of coal.

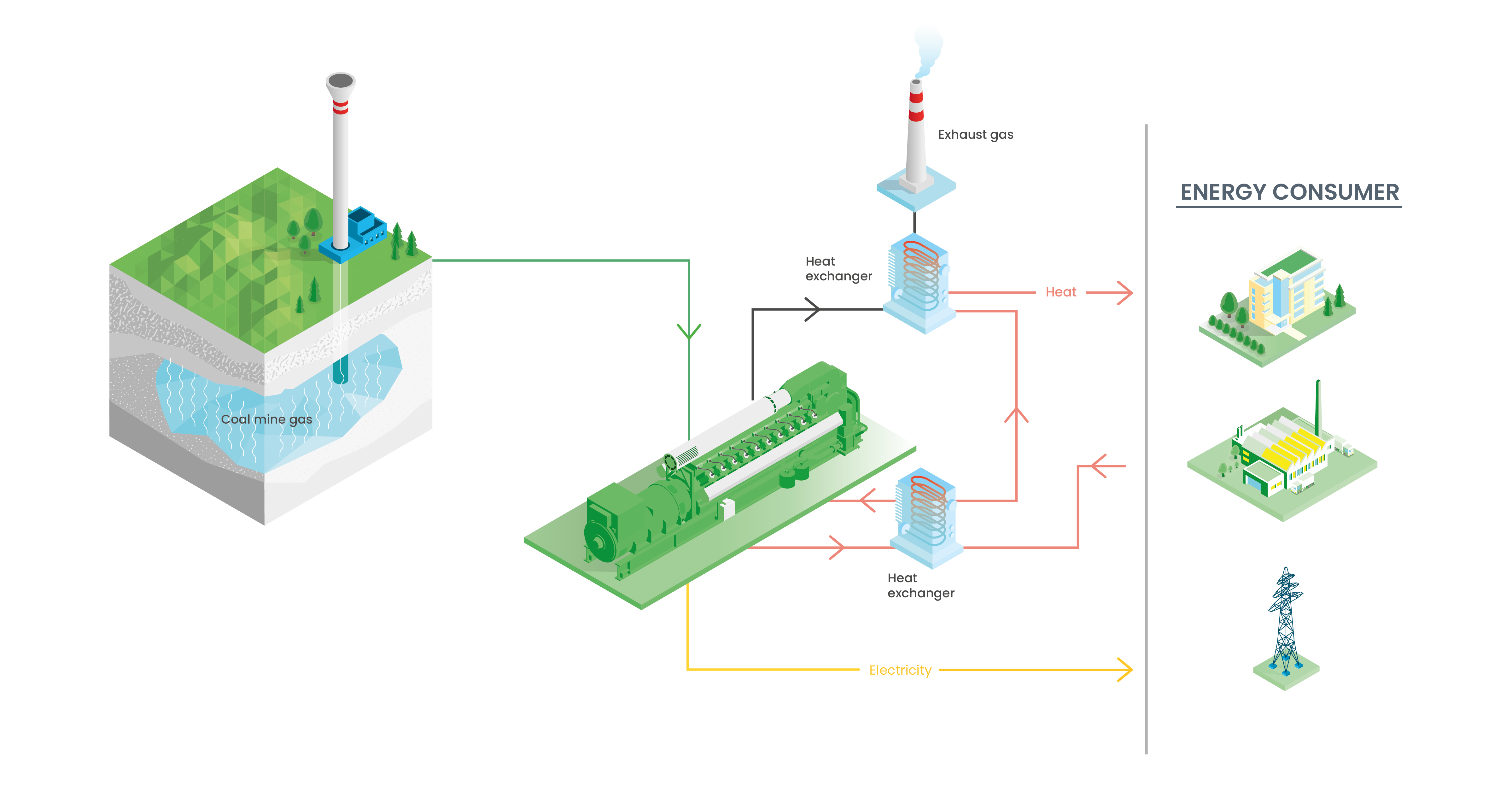

Coal mine gas develops during the geochemical conversion of organic substances to coal. It is present in fissures, faults and pores of coal seams and as adsorbed gas on the inner surface of coal and neighboring rock.

Our dedicated Jenbacher experts are available to provide personal consultation.

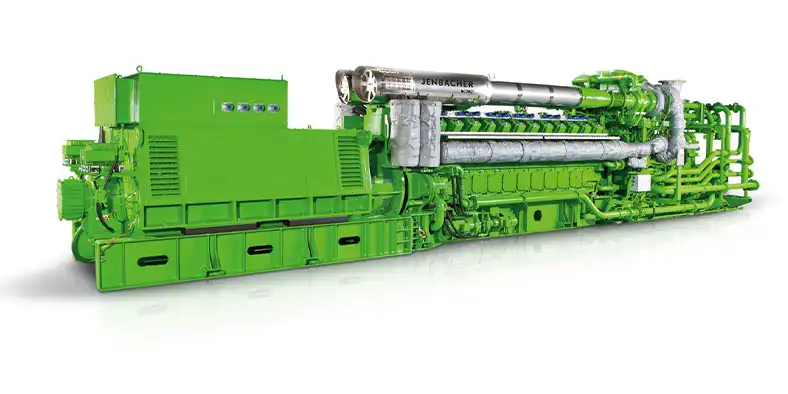

However, the potential danger of coal mine gas (CMG) and methane emissions can be greatly reduced when they are harnessed properly for power and heat generation. Since the early 1990s, Jenbacher gas engines product line, with an installed capacity of more than 400 MW running on coal mine gas worldwide, has provided solutions for this special application.

How does it work?

Today, most large underground hard coal mines potentially contain coal mine methane, and abandoned mine methane and can be effectively used for power and heat generation with gas engines.

Sudden changes in the composition of CMG put greater demands on the engine, however. INNIO offers a special gas mixing and engine control system that enables efficient use of this gas to a minimum CH4-concentration of only 25%.

Additionally, Jenbacher gas engines are designed to operate on full load, despite low gas pressure, high humidity, dust load, and altitude.

The generated energy can be used in the coal mine to meet electricity requirements or fed into the public power grid. Thermal energy can be used for onsite heating or fed into a district heating system.

Benefits of green mining

- Increased worker safety due to installation or refurnishing of gas suction system

- Mitigation of greenhouse gas (methane) and possible carbon monetization

- Revenues for power and heat production, when fed into the public grid

- Smooth operation despite fluctuations in gas pressure and methane content

- Overall efficiency of up to 90%, in combined heat and power, and up to 43.5% in power generation alone

- Zero to 100 percent load in 10 minutes

- Compact, modular units with low footprint requirement and dynamic weight

- Basic design and support for gas conditioning if required

- Low NOx yield from Dry Low Emissions (DLE) combustors

Selected Case Studies

Chengzhuang CBM (CHN)

through coalbed methane power generation

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Shanxi Jinju Hudi (CHN)

supporting China’s energy transition

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Chengzhuang CBM (CHN)

through coalbed methane power generation

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Shanxi Jinju Hudi (CHN)

supporting China’s energy transition

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Our experts are ready to help you!

Looking for onsite power solutions?

Need access to electricity? We’re there for you.

Want to lower your energy costs, or even sell electricity back to your local grid?

INNIO’s regional experts can help you figure out the Jenbacher solution that best meets your needs. With a free consultation, you can:

- Explore the advantages of onsite power generation solutions for your company

- Discover how to use economic modeling for added financial benefit

- Get answers on the technical aspects of your project—including fuel types, feasibility studies, and equipment and balance of plant selection

- Learn how to take advantage of regional incentive programs

- Review the delivery options for your project: purchasing, financing, leasing, and engaging a service provider, such as ESCO or BOO

- Find out how to meet emissions targets

Fill out the following contact form or send us an email to contact.en@innio.com. Let’s get started!

Consult an expert

Send us a message and we’ll contact you to start the conversation.

Whether your business is looking for onsite power solutions, access to electricity, decreased energy costs, or even to sell electricity back to your local grid/consumers, Jenbacher regional experts can advise you on which solution makes the most sense for you.